Processes

Toll Blending is a common service for chemical companies (e.g.: “toll blender”) to manufacture/fulfill chemistry blending for a partner in order to reduce the partner’s production risks or capital investments. RBP Chemical Technology works with partners around the globe to provide this service, as well as, to optimize their chemical processes. Here are six reasons why customers turn to RBP for their toll blending needs.

When companies have specific chemical needs but lack the resources to address these needs in house, outsourced chemical blending – or Toll Blending – is a valuable solution.

We take pride in is our core competency, and that’s being experts in surface chemistry. We understand the function of cause and effect of chemistry with all mediums, from printing press room, all the way to medical chemistry. When you use a press room, as an example, you’re touching many different surfaces. You’re touching everything from organic items like paper to aluminum plates and carbons. You’re also touching hydrocarbon substrates like plastics, all the way to using other chemistries, like ink. When it comes to chemistry handling, and we want you to do it safely. Here are our six solutions for safer chemistry handling.

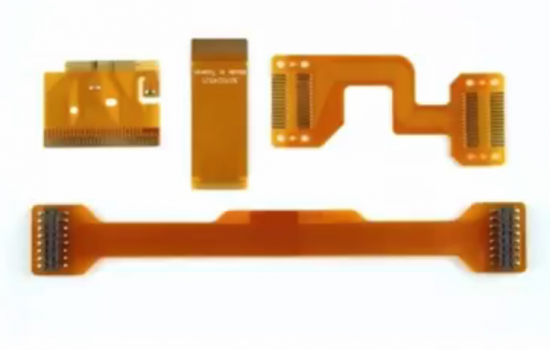

Flexible circuits were first introduced as a replacement for wire harnesses. The earliest versions date back to World War II. Today, flex and rigid flex circuits are filling an important role across multiple industries, include applications in the medical, automotive, and telecom fields.

Flexible circuits were first introduced as a replacement for wire harnesses. The earliest versions date back to World War II. Today, flex and rigid flex circuits are filling an important role across multiple industries, include applications in the medical, automotive, and telecom fields.

RBP Chemical Technology, Inc. is excited to announce that it has completed the transition to ISO 9001:2015 one year ahead of schedule.

ISO 9001 is a standard that sets out the requirements for a quality management system to enhance customer satisfaction through the effective application of the system, including processes for improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements.

For parts without colored oxide:

Minimum recommended process for electropolishing Titanium alloys

- Clean in MicroClean Ti™ (RDZ-1849) (Time and temperature to be determined, no such thing as “too much”)

- Water Rinse

- Alcohol Rinse

- ElectroPolish Ti2 (RDZ-1676), 300+ Amps/ft2, up to 10 minutes

OR

Generic Electropolish (70/30 Methanol/sulfuric) which you can make, or can purchase Nitinol Titanium ElectroPolish (RDZ-1867), used at 7-10 volts, ~50 Amps/ft2, and below -20 degrees C. If you are making this exciting blend, you may want to read “Control of Methanol-Sulfuric blends”.

If the polishing is non-uniform, the surface may be oxidized, and require a treatment after the MicroClean Ti™: MicroClean MV™ (RDZ-1995), which, although it is a strong acid de-oxidizer it will NOT remove metal.