Technical Toll Blending & Custom Chemicals

When manufacturers need specialized chemicals and mixtures, they turn to RBP for comprehensive toll manufacturing, contract manufacturing, and toll processing.

What is Toll Blending?

Our experienced chemists and supply chain teams will partner with you to formulate, scale-up, blend, package, label, warehouse and deliver custom chemistry — to your location or a specified third party.

- Proven capabilities with technical toll blending and supply chain solutions

- Custom and proprietary formulas for surface chemistry, coatings and specialty solvents

- Inventory management and distribution for just-in-time delivery

- ISO 9001 compliant US-based and international manufacturing facilities with global logistics expertise

- Extensive production capacity and flexible packaging options of any size — from one quart to bulk truckload shipments

Everything You Want to Know About Toll Blending

RBP’s world-class manufacturing facilities contain high-end, precision toll blending equipment — including variable-speed mixing systems for producing your chemicals products guaranteed to meet your performance requirements. To ensure your batches never vary, every blended batch receives careful attention to the same tight tolerances. And RBP maintains product retains for one year to confirm all quality and performance characteristics long-term.

By leveraging a wealth of global production and distribution capabilities, RPB’s focus on high technology products and in-depth support from the technical service team allows you to maximize productivity and minimize cost.

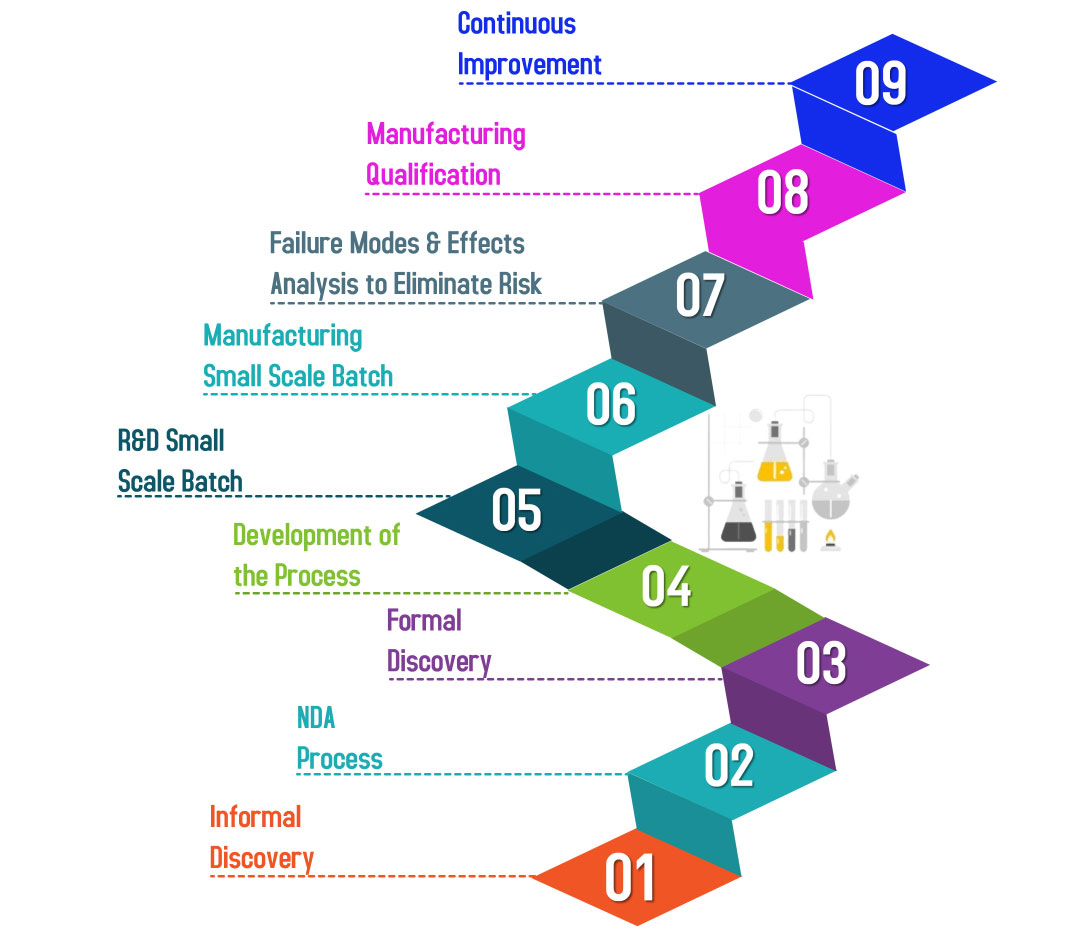

RBP Exclusive 9 Step Process

- Informal Discovery

- NDA Process

- Formal Discovery

- Development of the Process

- R&D Small Scale Batch

- Manufacturing Small Scale Batch

- Failure Modes & Effects Analysis to Eliminate Risk

- Manufacturing Qualification

- Continuous Improvement

Informal Discovery

Our first step it to ensure that RBP is the right fit for you. After a brief introductory meeting, many of the following questions will be answered: Is there Mutual Interest? Do we want to work together? Is RBP the right fit?

Non-Disclosure Agreement (NDA) Process

Our utmost initial priority is to ensure protection of your intellectual property, trade secrets, and confidentiality. We have a 2-way boilerplate agreement or we are open to using your documents.

Formal Discovery

This step is key in ensuring that many of your key requirements can be met:- Manufacturing requirements

- Regulatory and safety requirements

- Technical requirements (e.g.: analytical testing and methods)

- Packaging requirements

- Storage Requirements

- Shipping requirements

- Supply chain requirements (inventory, safety stock, MIN/MAX points)

Development of the Process (“Batch Ticket” and Instructions and SOPs)

This step codifies your requirements to ensure repeatability and reproducibility of every batch:- PPE

- Procedures and Order of Addition

- Raw Material and Finished goods lot number traceability

- Packaging requirements

- Regulatory Requirements

R&D Small Scale Batch

Before we every manufacture a batch, our Research and Development (R&D) Team conducts a small scale batch to ensure the “process” meets all of your requirements.

Manufacturing Small Scale Batch

After a small-scale R&D batch, our manufacturing team will produce its initial small-scale batch to ensure “scale-up” and process documentation are validated. During this step, our Quality Control and/or R&D team will overwatch the process and identify any risks.

Failure Modes and Effects Analysis (FMEA) to Eliminate Risk

We strive to eliminate any residual risks identified during initial small-scale manufacturing. If warranted, we will also execute a “Management of Change” process for your blends.

Manufacturing Qualification

After risk mitigation and final people/process control implementation, we will qualify the batch after the appropriate amount of blends is produced.

Mutual Refinement (safety, quality, delivery, and cost improvements)

We strive to identified, share, and jointly refine any product or process steps that will improve your requirements and objectives. Simply put, consider us a “partner” with the goal of continuous improvement and providing you with the best product and service possible.Types of Toll Blending

Turnkey

The customer only provides the formula or recipe of the specialized compound. Toll blender takes care of production, quality control, packaging and delivery.

Service

The customer provides the formula, raw materials, packaging, and all specifications. Toll blender provides only the “blending” service based upon a delivery schedule.

Hybrid

A “mix” of the Service and Turnkey models based on customer’s business model and requirements.

Benefits of Toll Blending

Resources

As a company that produces chemistry with a wide range of features, we know how important it is to highlight the benefits of each one. That's why we frequently release visual content that helps customers understand what makes our products superior.

Get Started

15-MINUTE VIRTUAL

CONSULTATION

Join our team of chemists and experts via Microsoft Teams to conduct “discovery” of your chemistry process opportunities and challenges.

SEND US YOUR

PARTS/PROTOTYPES

We specialize in custom blends, high-tech analytical testing and formula development.