News and Events

Ernie Litynski, President, RBP Chemical Technology

MILWAUKEE, Wisconsin — RBP Chemical Technology and Lighteum have entered into a collaborative partnership focused on Nitinol device development and processing. Recognizing that each company brings best-in-class technical capabilities in their areas of expertise, coupled with a spirit of openness and cooperation, it became quite apparent that the two companies should formalize their working relationship.

A few years ago, a partner came to us with a difficult assignment. They were producing a mix of a volatile acid, something like 99% sulfuric acid with an alcohol solvent, in house. They needed to reduce the cost of producing and storing this chemical while also lowering risks to their employees.

A few years ago, a partner came to us with a difficult assignment. They were producing a mix of a volatile acid, something like 99% sulfuric acid with an alcohol solvent, in house. They needed to reduce the cost of producing and storing this chemical while also lowering risks to their employees.

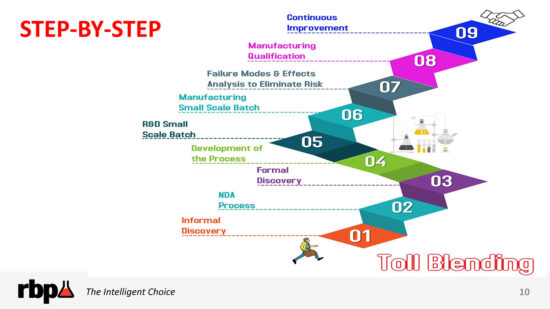

We get asked this question all the time: How does it work if I really want to outsource some of my chemical manufacturing to a toll blender? Toll Blending is a common service for chemical companies (e.g.: “toll blender”) to manufacture/fulfill chemistry blending for a partner to reduce the partner’s production risks or capital investments. RBP Chemical Technology works with partners around the globe to provide this service, as well as, to optimize their chemical processes.

We get asked this question all the time: How does it work if I really want to outsource some of my chemical manufacturing to a toll blender? Toll Blending is a common service for chemical companies (e.g.: “toll blender”) to manufacture/fulfill chemistry blending for a partner to reduce the partner’s production risks or capital investments. RBP Chemical Technology works with partners around the globe to provide this service, as well as, to optimize their chemical processes.

SAN DIEGO, California — RBP Chemical Technology, known for consistently delivering high-quality products and services, based in Milwaukee, Wisconsin announced their exclusive partnership today with Schlötter GmbH based in Geislingen, Germany.

Toll Blending is a common service for chemical companies (e.g.: “toll blender”) to manufacture/fulfill chemistry blending for a partner in order to reduce the partner’s production risks or capital investments. RBP Chemical Technology works with partners around the globe to provide this service, as well as, to optimize their chemical processes. Here are six reasons why customers turn to RBP for their toll blending needs.

When companies have specific chemical needs but lack the resources to address these needs in house, outsourced chemical blending – or Toll Blending – is a valuable solution.

RBP Chemical Technology, Inc. is adding to its leadership team with the appointment of Dan Carey as Executive Vice President.

RBP Chemical Technology, Inc. is adding to its leadership team with the appointment of Dan Carey as Executive Vice President.

We take pride in is our core competency, and that’s being experts in surface chemistry. We understand the function of cause and effect of chemistry with all mediums, from printing press room, all the way to medical chemistry. When you use a press room, as an example, you’re touching many different surfaces. You’re touching everything from organic items like paper to aluminum plates and carbons. You’re also touching hydrocarbon substrates like plastics, all the way to using other chemistries, like ink. When it comes to chemistry handling, and we want you to do it safely. Here are our six solutions for safer chemistry handling.

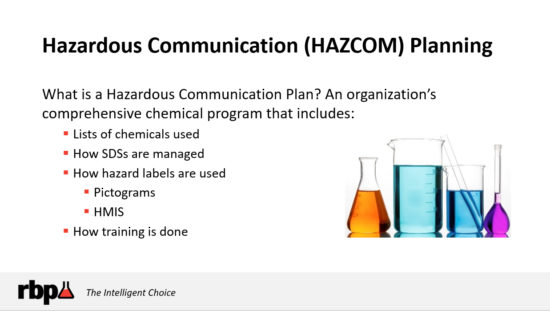

We firmly believe that chemistry provides the perfect solutions to polish, passivate, deoxidize and coat medical implant devices. And while these chemicals are made to help, they can also do a lot a harm if misused or mistreated.

Hazardous communications are the most important part of chemistry in any industry, but it’s especially important in the Medical Implant Device industry.

Hazardous communications are the most important part of chemistry in any industry, but it’s especially important in the Medical Implant Device industry.